When it comes to optimizing energy efficiency in commercial refrigeration, selecting the right freezer motor is a critical factor that can significantly impact operational costs and overall performance. The freezer motor not only drives the cooling mechanism but also influences the energy consumption of your refrigeration system. In this guide, we will explore the various aspects that one should consider when choosing a freezer motor, including the motor type, its energy rating, compatibility with existing systems, and the specific cooling requirements of your operation. Understanding these elements will empower business owners and facility managers to make informed decisions that not only enhance efficiency but also contribute to sustainable practices within the commercial refrigeration sector. By focusing on the right freezer motor, you can ensure that your refrigeration system operates at peak efficiency, leading to reduced energy costs and increased reliability.

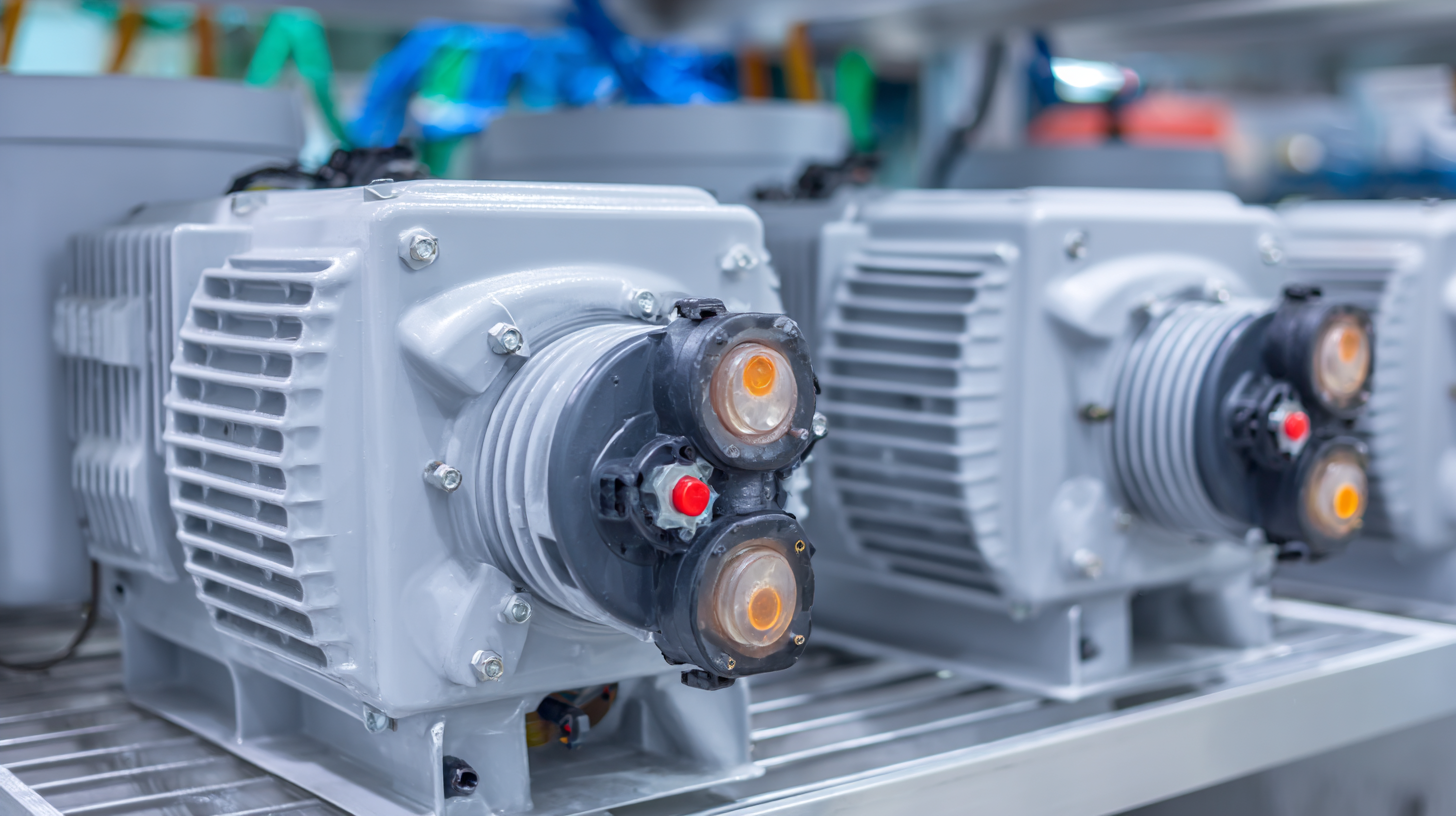

When choosing the right freezer motor for commercial refrigeration, understanding the various types available is essential for achieving optimal energy efficiency. Different freezer motors, including traditional induction motors, synchronous motors, and advanced EC (electronically commutated) motors, cater to varying refrigeration needs. Induction motors are widely used due to their reliability and simplicity, while synchronous motors offer improved efficiency. On the other hand, EC motors stand out with their ability to adjust speed dynamically, significantly reducing energy consumption and operational costs.

The commercial refrigeration equipment market is poised for growth, which emphasizes the importance of selecting innovative motor technologies. For instance, recent advancements have introduced motors that not only reduce energy usage in supermarkets but also enhance overall system performance. By evaluating the specific requirements of their refrigeration systems and the benefits of each motor type, businesses can make informed decisions that align with their energy efficiency goals. The shift toward more efficient motor technology is a vital step in supporting sustainability initiatives in the commercial refrigeration sector.

When selecting a freezer motor for commercial refrigeration, several key factors must be evaluated to ensure optimal energy efficiency. One of the primary considerations is the motor's energy rating. Motors that are certified by energy efficiency programs, such as ENERGY STAR, typically use less power while providing the same cooling performance, resulting in lower operational costs over time. Additionally, understanding the specific cooling demands of the application can help in choosing a motor with the appropriate horsepower and efficiency level, preventing energy waste due to over- or under-sized equipment.

Another important aspect is the type of compressor the motor drives. Different compressor types, including reciprocating and scroll compressors, have varied efficiency ratings. Selecting a freezer motor that matches the characteristics of the compressor can enhance overall system performance. Lastly, the motor’s speed control options, such as variable speed drives, allow for adjusted power consumption based on the actual cooling load, leading to improved energy savings. Investing time in understanding these key factors will significantly contribute to achieving energy efficiency in commercial refrigeration systems.

When it comes to choosing a freezer motor for commercial refrigeration, understanding the difference between single-phase and three-phase motors is crucial for optimal energy efficiency. Single-phase motors are typically easier to install and maintain, making them a popular choice for smaller refrigeration units. However, they often struggle with larger loads, resulting in lower energy efficiency and higher operational costs in the long run.

On the other hand, three-phase motors are designed for larger systems and offer superior performance for heavy-duty applications. They provide consistent power, which translates into better efficiency and lower energy consumption. Additionally, three-phase motors generally have a longer lifespan and require less frequent repairs, making them a more economical choice for larger commercial operations.

**Tips:** To maximize energy efficiency, consider your refrigeration unit's size and load demands before making a decision. Regularly maintain your motor by checking for wear and ensuring proper alignment, which can help prolong its lifespan. Additionally, always consult with a certified technician to determine the best motor type suited to your specific refrigeration needs.

| Motor Type | Power Consumption (W) | Efficiency Rating | Initial Cost ($) | Maintenance Cost (Annual) ($) | Lifespan (Years) |

|---|---|---|---|---|---|

| Single-Phase | 1500 | 85% | 250 | 100 | 10 |

| Three-Phase | 1200 | 90% | 450 | 80 | 15 |

Choosing the right freezer motor is crucial for ensuring optimal energy efficiency in commercial refrigeration systems. One key factor to consider is the compatibility of the motor with the refrigeration unit's size and cooling requirements. According to a report by the Department of Energy (DOE), improperly sized motors can lead to significant energy losses—up to 30%—as they either overwork or operate inefficiently. It is essential to evaluate the cubic footage of the freezer and the temperature range required to select a motor that meets these specifications without excess energy expenditure.

Furthermore, efficiency ratings and motor technologies also play a significant role. The latest industry standards indicate that EC (Electronically Commutated) motors are 30% more efficient than traditional shaded-pole or permanent split capacitor motors. This is particularly relevant when looking at systems with high run times. Such motors offer variable speed options that adapt to the cooling load, minimizing energy consumption during periods of low demand. Incorporating an appropriately sized and energy-efficient motor can significantly lower operational costs, making it a vital step in optimizing commercial refrigeration systems.

When it comes to maintaining freezer motors in commercial refrigeration, proper care can significantly enhance both longevity and efficiency. Regular maintenance is key. First, ensure that the motor is kept clean and free of dust. Dust accumulation can lead to overheating and reduce operational efficiency. A simple monthly dusting can make a big difference.

Another essential tip is to regularly inspect the motor for any signs of wear and tear, such as frayed wires or unusual noises. Addressing these issues promptly can prevent more significant problems and preserve the motor’s performance. Additionally, lubricating the motor bearings as recommended by the manufacturer can help reduce friction, allowing the motor to run more smoothly and prolonging its life.

Lastly, consider the ambient temperature where the freezer motor operates. Keeping the surrounding area well-ventilated can prevent overheating. It’s essential to monitor the surroundings and proactively manage the environment to ensure optimal motor performance. Implementing these simple yet effective maintenance tips can result in significant improvements in both energy efficiency and the lifespan of your freezer motors.