In the ever-evolving landscape of refrigeration systems, choosing the appropriate access valve is crucial for ensuring optimal performance and maintenance. Access valves for refrigeration play a significant role in facilitating efficient service interventions, particularly in complex systems where minimizing downtime and maximizing operational efficiency are paramount. According to the "2021 HVACR Market Research Report," over 70% of service professionals reported that proper access points significantly reduce service time and enhance system reliability. Furthermore, the International Institute of Refrigeration (IIR) indicates that improper valve selection can lead to a 30% increase in energy consumption and premature equipment failure. With these factors in mind, understanding the nuances of access valve selection becomes imperative for technicians and system designers looking to enhance the longevity and efficiency of refrigeration systems.

Access valves play a crucial role in refrigeration systems by providing a means to access the refrigerant for maintenance and diagnostics. These valves allow technicians to connect various tools, such as pressure gauges and refrigerant recovery machines, directly to the system without compromising its integrity. Their design ensures that the refrigerant can be safely measured, charged, or recovered, minimizing the risk of contamination and ensuring efficient operation.

When selecting the right access valve for a refrigeration system, it is essential to consider factors such as valve size, type, and compatibility with the refrigerant being used. Common access valve types include standard Schrader valves and service valves, each with its advantages depending on the application. Additionally, the valve’s placement within the system is vital for optimal performance and to facilitate easier access during servicing. By understanding the function and importance of access valves, HVAC professionals can ensure reliable refrigeration system performance while extending the equipment's lifespan.

When selecting access valves for refrigeration systems, several key factors should be carefully considered to ensure optimal performance and reliability. One of the most critical factors is the type of refrigerant being used. According to a report by the International Institute of Refrigeration, the choice of access valve can greatly affect the efficiency of the system and its compatibility with certain refrigerants. For instance, high-pressure refrigerants require valves that can withstand greater stress and have appropriate seals to prevent leaks.

Another important consideration is the size and configuration of the valve. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends that access valves should be selected based on the specific dimensions and layout of the refrigeration system. A mismatch can lead to inefficiencies and increased maintenance costs. Data shows that properly sized access valves can improve system performance by up to 15%, reducing energy consumption and prolonging the life of the equipment.

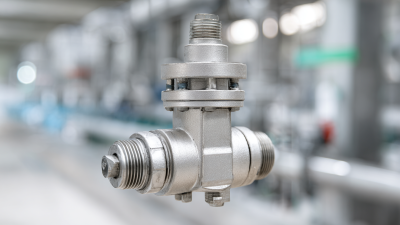

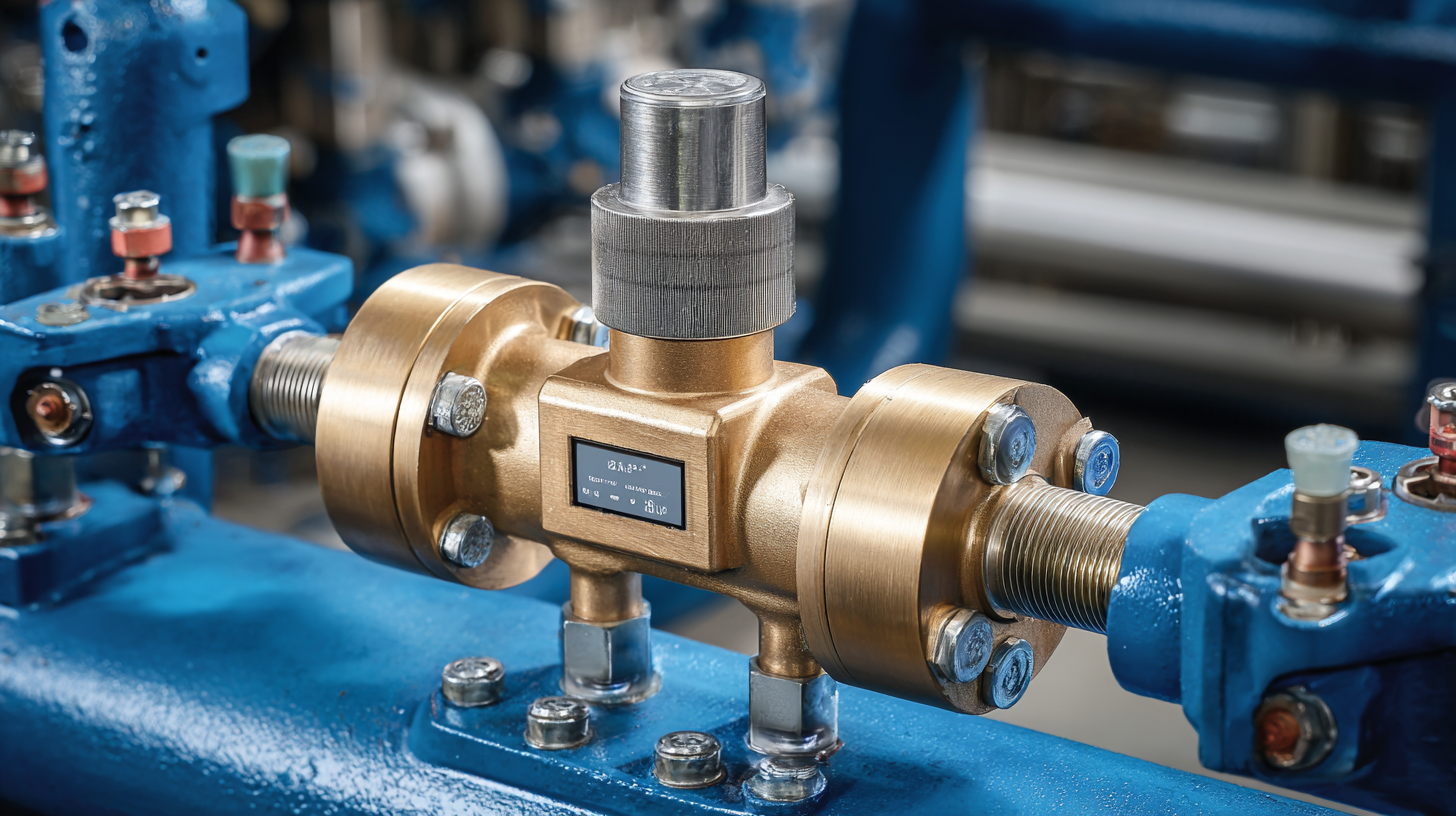

Lastly, the material of the valve plays a significant role in ensuring durability and resistance to corrosion. A study by the Refrigeration Research Council highlights that stainless steel valves, although more expensive, can significantly reduce maintenance frequency compared to their brass counterparts, as they offer better resistance to moisture and chemical exposure. Therefore, taking into account the refrigerant type, valve size, and material will aid in making an informed selection that optimizes the performance of refrigeration systems.

When selecting access valves for refrigeration systems, understanding the different types available and their specific applications is crucial.

Common access valves include service valves, core removal valves, and ball valves.

Service valves are essential for routine maintenance and allow for easy refrigerant access, while core removal valves enable technicians to change the valve core without losing refrigerant.

Ball valves, on the other hand, offer a reliable seal and smooth flow, making them ideal for high-pressure applications.

Tips: When choosing an access valve, consider the refrigerant type you’ll be using, as some valves are not compatible with certain refrigerants.

Additionally, ensure the valve’s size matches the piping to maintain optimal system performance.

Another important type is the manifold valve, which is used for connecting gauges during system diagnostics.

These valves help technicians assess pressure levels and diagnose issues effectively.

It's vital to choose valves that are easy to reach and operate to streamline maintenance tasks and reduce downtime.

Tips: Regularly inspect your access valves for any signs of wear or leakage, and ensure that they are easily accessible for routine checks.

This proactive approach can significantly extend the lifespan of your refrigeration system.

When it comes to ensuring optimal access valve performance in refrigeration systems, proper installation practices are crucial. Start by selecting access valves that are compatible with your specific system requirements. Look for features such as robust materials that can withstand refrigerant pressures and temperatures. Proper placement of the valves is also essential; they should be installed in easily accessible locations to facilitate maintenance and repairs.

During installation, ensure that you follow the manufacturer's guidelines closely. This may include using the right tools and techniques to avoid leaks or damage. Pay special attention to torque specifications when securing the valves, as overtightening can lead to mechanical failure. Additionally, consider incorporating dynamic hydronic balancing techniques if applicable, which can enhance overall system efficiency and operational performance, ultimately benefiting your refrigeration setup.

To ensure the longevity of access valves in refrigeration systems, implementing effective maintenance practices is essential. Regular inspection is a key component in this process. Technicians should routinely check for signs of wear or corrosion, as these issues can compromise the valve's seals and overall functionality. Identifying problems early can minimize the risk of leaks and system failure, ultimately extending the life of the valves.

Moreover, proper cleaning is critical for maintaining access valves. Accumulation of debris or contaminants can hinder valve performance. Using appropriate cleaning solutions and methods that match the materials of the valve will help ensure that they remain unobstructed and in good working order. Additionally, technicians should follow the manufacturer’s recommendations for maintenance intervals and procedures, as adherence to these guidelines can prevent premature wear and enhance operational efficiency. By prioritizing these maintenance practices, users can significantly prolong the life of access valves in refrigeration systems.