Choosing the right access valve for refrigeration is a crucial decision that can significantly impact system efficiency and maintenance costs. As the refrigeration industry evolves, it is essential to understand the variety of available access valves and their specific applications. According to a report by the International Institute of Refrigeration, improper valve selection can lead to a 15-20% increase in energy consumption and a decrease in the longevity of refrigeration systems.

Access valves allow for routine maintenance, repair, and system monitoring, making it critical for professionals to select the most appropriate type for their needs. With a comprehensive understanding of the features, materials, and compatibility of access valves for refrigeration systems, stakeholders can ensure optimal performance and reliability, ultimately enhancing the sustainability and functionality of their refrigeration setups.

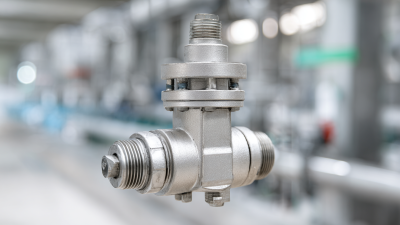

When it comes to refrigeration systems, access valves play a crucial role in maintenance and servicing. Understanding the different types of access valves is essential to ensure optimal performance and longevity of your system. There are mainly two types of access valves: piercing valves and standard access valves. Piercing valves are designed to penetrate the insulation of a refrigeration line, allowing for easier access in tight spaces, while standard access valves are utilized for direct access during servicing and troubleshooting.

When choosing the right access valve, consider the system's size and configuration. Larger systems might benefit from multiple standard access valves strategically placed for convenience. Another tip is to ensure compatibility with the refrigerant type in your system, as different valves are designed for specific refrigerants. Additionally, check the durability and pressure ratings of the valve; investing in high-quality valves can prevent leaks and potential system failures. By keeping these tips in mind, you can select the access valve that best meets your refrigeration needs.

When selecting access valves for refrigeration systems, several key factors must be considered to ensure optimal performance and reliability. First, the type of refrigerant used in the system is crucial. Different refrigerants have varying properties, and access valves must be compatible with these to prevent leaks and ensure efficient operation. For instance, valves designed for R410A might not be suitable for R134a due to their differing chemical compositions and pressures.

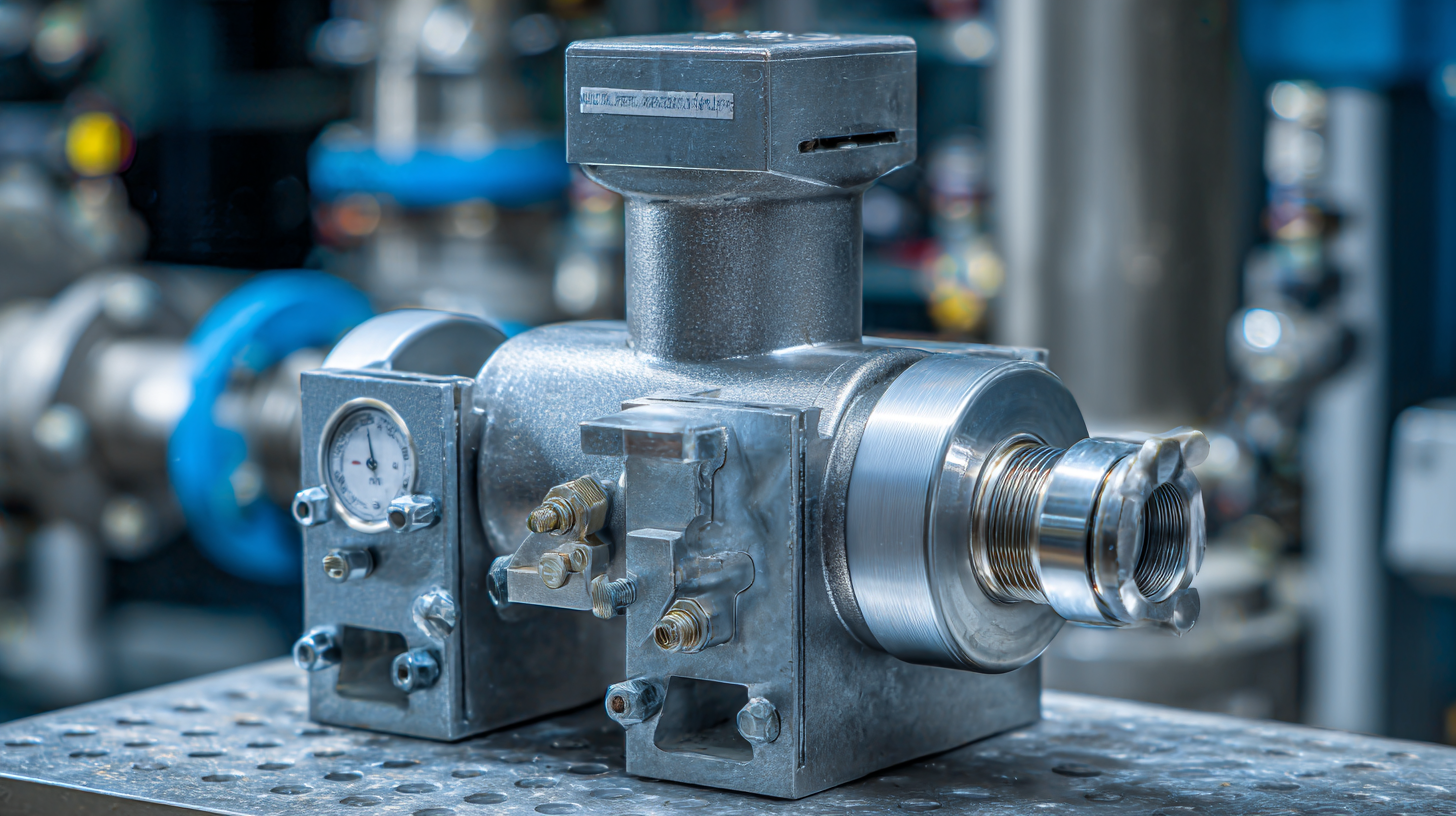

Another important factor is the valve’s size and configuration. The size should match the refrigerant line to facilitate proper flow without restriction. Additionally, the configuration of the valve – such as whether it is a ball valve or a gate valve – can impact serviceability and maintenance. A ball valve, for example, offers a better sealing mechanism, while a gate valve may be chosen for its lower pressure drop. Evaluating the installation requirements, including space constraints and accessibility for maintenance, further helps in selecting the right access valve, ensuring both functionality and ease of service in the refrigeration system.

| Tip | Description | Key Considerations | Common Applications |

|---|---|---|---|

| 1. Understand System Design | Review the specific requirements of your refrigeration system. | System pressure, temperature ranges, and fluid characteristics. | Commercial refrigeration, HVAC units. |

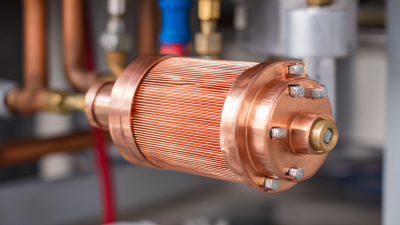

| 2. Material Selection | Choose the right materials for durability and compatibility. | Corrosion resistance, temperature stability. | Refrigeration lines, piping systems. |

| 3. Size Appropriately | Select the right size for efficient operation and maintenance. | Flow rates, connection sizes, space availability. | Chillers, refrigeration systems. |

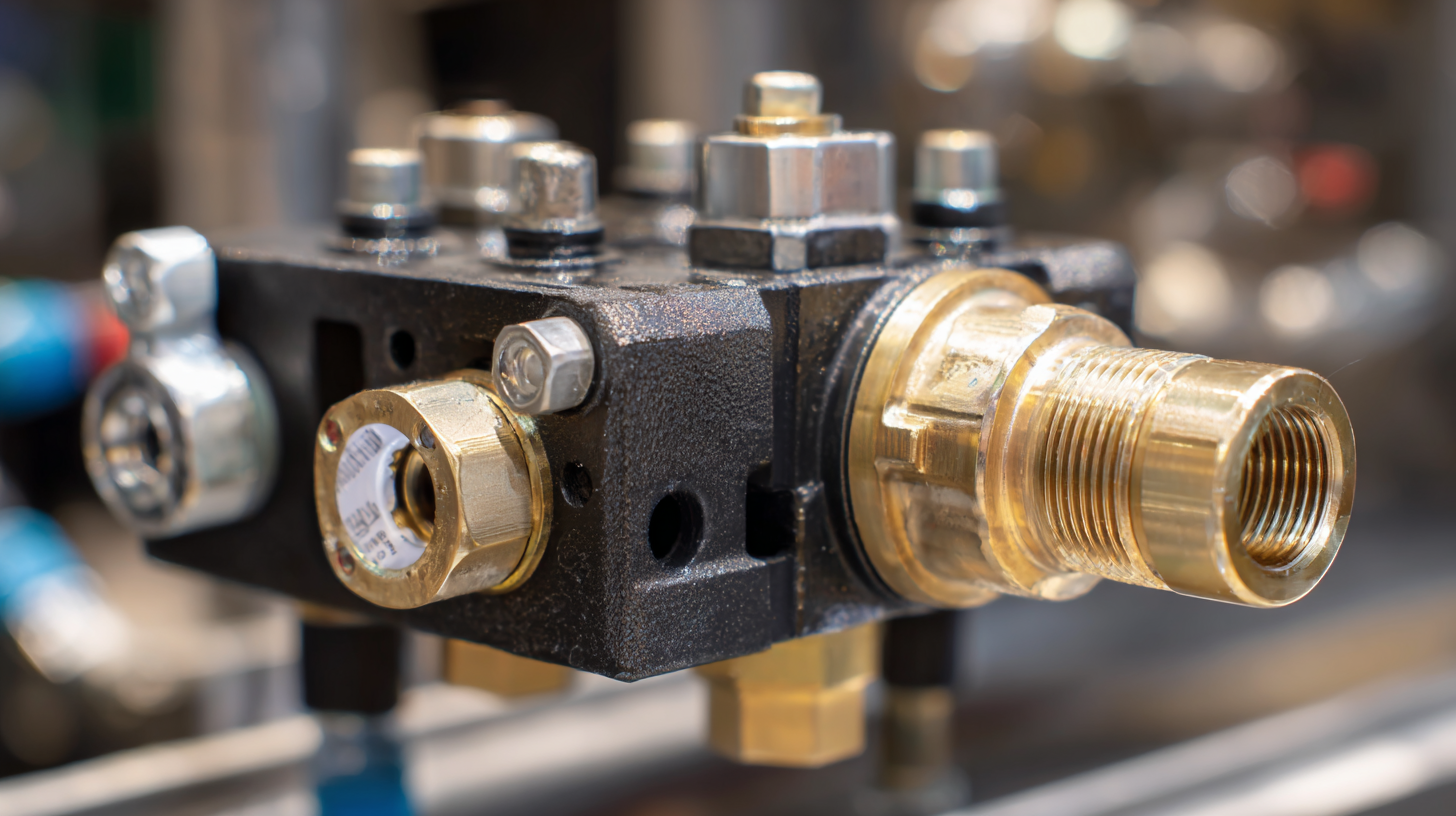

| 4. Ensure Proper Valving Type | Select the type of valve that matches system needs. | Ball, gate, or check valves based on application. | Home refrigeration, industrial cooling. |

| 5. Consult Professionals | Seek advice from experts for best practices. | Industry standards, compliance requirements. | Large scale refrigeration, commercial applications. |

When selecting access valves for refrigeration systems, understanding the compatibility between valve types and various refrigerants is critical. With the phase-down of high global warming potential (GWP) refrigerants, such as R-410A, and the introduction of lower-GWP alternatives like A2L refrigerants, professionals in the field must ensure that their equipment is suitable for the new cooler technologies. A2L refrigerants offer benefits in terms of less environmental impact, but they come with different pressures and characteristics compared to traditional refrigerants.

Choosing the right access valve involves more than just ensuring it fits physically within the system. Valves must be rated for the specific refrigerant type to prevent issues such as leaks or compatibility failures.

For instance,

valves that are designed for A1 refrigerants may not necessarily work with A2L refrigerants, given the differences in pressure ratings and material compatibility.

Therefore, conducting thorough research and consulting manufacturer guidelines can prevent potential system failures and ensure efficient operation in air conditioning and refrigeration applications.

When selecting the right access valve for refrigeration systems, evaluating the size and configuration is crucial for optimal performance. A well-chosen valve can significantly enhance efficiency and reduce operational costs. Recent industry reports indicate that the market for pilot-operated pressure relief valves is forecasted to grow from USD 1.5 billion in 2024 to USD 2.5 billion by 2033, underscoring the increasing importance of precise valve selection across refrigeration applications.

Moreover, considerations such as the valve's expandability and the effective orifice area are essential. It has been noted that valve performance, particularly in systems with specific configurations, can be substantially impacted by parameters like diameter expansion and leaflet overhang. Optimizing valve dimensions not only supports energy efficiency but also aligns with the trend towards integrating advanced technologies in refrigeration cycles. As businesses strive for lower emission systems, access valves must be configured to accommodate innovative energy solutions, including those powered by renewable resources.

This chart illustrates the performance ratings of various sizes of access valves used in refrigeration systems. Performance ratings are critical for selecting the appropriate valve size, ensuring optimal functionality and efficiency.

To ensure the longevity of access valves in refrigeration systems, regular maintenance is crucial. One key practice is to inspect the valves for any signs of wear or damage. This includes checking for leaks, corrosion, or blockages that can impair functionality. By performing these inspections routinely, technicians can identify potential issues before they escalate, thereby extending the lifespan of the valves.

To ensure the longevity of access valves in refrigeration systems, regular maintenance is crucial. One key practice is to inspect the valves for any signs of wear or damage. This includes checking for leaks, corrosion, or blockages that can impair functionality. By performing these inspections routinely, technicians can identify potential issues before they escalate, thereby extending the lifespan of the valves.

Cleaning access valves is another important aspect of maintenance. Accumulated debris and contaminants can hinder the valve's operation and efficiency. Utilizing a suitable cleaning solution and soft brushes can effectively remove unwanted material without damaging the valve itself. Additionally, lubricating the valve components can help ensure smooth operation, preventing unnecessary wear and tear. Regular maintenance not only enhances the efficiency of refrigeration systems but also helps in minimizing costly repairs and downtime.