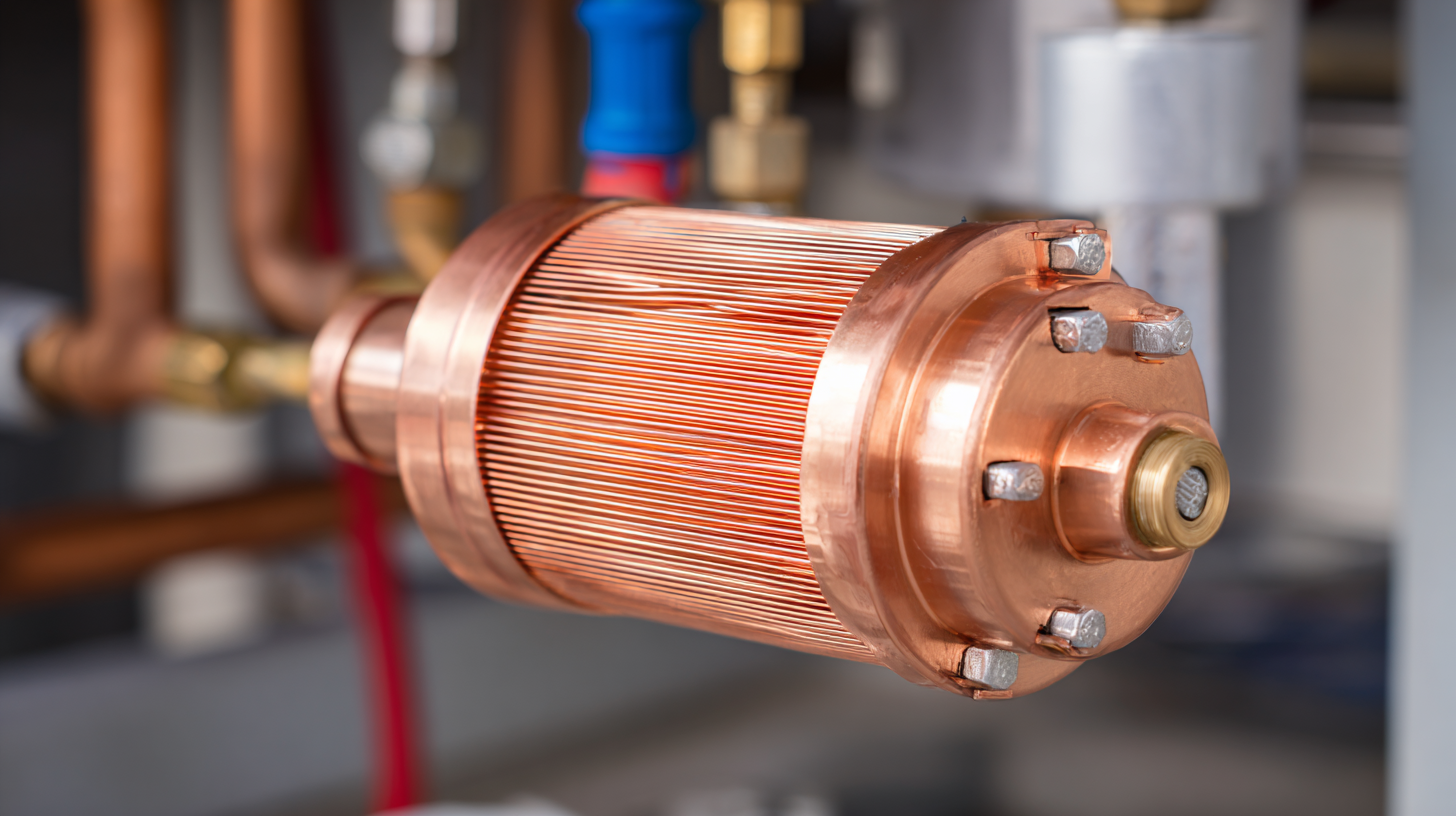

In the realm of HVAC systems, selecting the appropriate copper filter drier is crucial for ensuring optimal performance and longevity. According to a report by the U.S. Department of Energy, maintaining a well-functioning HVAC system can improve energy efficiency by up to 30%, significantly lowering operational costs and environmental impact.

Copper filter driers play a vital role in this process by removing moisture, particulates, and acid contaminants from refrigerants, thus safeguarding the internal components of the system.

With varying types and specifications available in the market, it becomes essential for technicians and contractors to understand the distinct advantages and limitations of each filter drier.

This article aims to provide expert tips and industry insights to help you make an informed decision when selecting a copper filter drier that meets your HVAC performance needs.

Copper filter driers play a vital role in this process by removing moisture, particulates, and acid contaminants from refrigerants, thus safeguarding the internal components of the system.

With varying types and specifications available in the market, it becomes essential for technicians and contractors to understand the distinct advantages and limitations of each filter drier.

This article aims to provide expert tips and industry insights to help you make an informed decision when selecting a copper filter drier that meets your HVAC performance needs.

Copper filter driers play a crucial role in HVAC systems by ensuring the efficient and reliable operation of cooling and heating processes. They are essential for removing moisture, acids, and other contaminants from refrigerants, which can significantly improve the longevity and performance of the entire system. According to industry data, moisture in the system can lead to corrosion and, ultimately, compressor burnout—a common and costly issue for HVAC contractors. Implementing a proper filtering system, including high-quality copper filter driers, can mitigate these risks, thus enhancing HVAC performance and customer satisfaction.

Copper filter driers play a crucial role in HVAC systems by ensuring the efficient and reliable operation of cooling and heating processes. They are essential for removing moisture, acids, and other contaminants from refrigerants, which can significantly improve the longevity and performance of the entire system. According to industry data, moisture in the system can lead to corrosion and, ultimately, compressor burnout—a common and costly issue for HVAC contractors. Implementing a proper filtering system, including high-quality copper filter driers, can mitigate these risks, thus enhancing HVAC performance and customer satisfaction.

Moreover, as refrigerant regulations evolve, particularly with the transition from R-410A to newer alternatives, the significance of selecting the right filter drier becomes even more vital. A recent report indicates that HVAC systems equipped with suitable filter driers can improve energy efficiency by up to 15%, leading to substantial cost savings over time. Contractors must stay updated on these industry shifts and ensure that they utilize the correct filter driers to maintain system efficacy, minimize refrigerant loss, and avoid the headaches associated with improper system operations.

When selecting the right copper filter drier for your HVAC system, it's crucial to consider several key factors that can significantly affect performance. First and foremost, assess the operating conditions of your system. This includes factors such as temperature, humidity, and potential contaminants within the refrigerant. A filter drier that is specifically designed to handle the environmental conditions will ensure optimal efficiency and longevity. It's also important to look into the filtration capacity—choosing a filter drier with the appropriate size and specifications can prevent blockages and maintain smooth operation.

Moreover, the quality of the materials used in the construction of the filter drier should not be overlooked. High-purity copper, for instance, is vital not only for durability but also for reducing wear and tear over time. Given the recent trends in copper pricing, investing in a high-quality filter drier is essential to avoid recurring costs associated with replacements or repairs due to inferior products. Additionally, keep an eye on the integration of newer technologies or environmentally-friendly materials that can enhance performance while minimizing ecological impacts, especially as industries increasingly prioritize sustainable practices.

When selecting a copper filter drier for your HVAC system, understanding the sizing and specifications is critical for ensuring optimal performance. The first step in this process is calculating the proper capacity required for your system. Typically, this involves assessing the refrigerant load and flow rates. For residential applications, a filter drier rated for 1 to 5 tons is common, while larger commercial systems may require units that can handle significant flow capacities. Ensuring that the filter drier is matched to the HVAC unit's size prevents issues such as reduced efficiency or premature wear.

Additionally, pay attention to the physical size and connection type of the filter drier. A unit that fits snugly within your HVAC layout and has connections compatible with your existing lines will facilitate a smoother installation process. Look for key specifications, including the moisture absorption capacity and pressure drop characteristics. Filters that can tolerate high moisture levels and maintain low pressure drops are ideal as they will contribute to the longevity and efficiency of the HVAC system. Investing time in choosing a filter drier that meets these criteria will lead to enhanced reliability and performance in your heating and cooling applications.

This chart displays the recommended specifications for selecting the right copper filter drier for optimal HVAC performance. The dimensions, capacities, and compatibility with refrigerants play a crucial role in ensuring efficient operation.

When it comes to choosing the right copper filter drier for your HVAC system, avoiding common pitfalls is essential to ensure optimal performance. One frequent mistake is underestimating the size and capacity needed for your specific application. Many technicians opt for a standard size without considering the cooling load or the system's requirements, which can lead to inadequate moisture absorption and increased wear on components. Always evaluate the specifications of your HVAC system and choose a filter drier that matches its capacity and compatibility.

Another common error is neglecting material quality and construction features. Not all copper filter driers are created equal; it’s crucial to avoid low-quality products that may not withstand the operating conditions of your system. Selecting an inferior filter drier can result in premature failure and additional maintenance costs. Instead, focus on reputable brands that provide detailed information about their product designs, including corrosion resistance and pressure ratings, to ensure you're making an informed decision. By steering clear of these mistakes, you can enhance the reliability and efficiency of your HVAC system.

| Criteria | Recommendations | Common Mistakes |

|---|---|---|

| Type of Refrigerant | Ensure compatibility with the refrigerant used in the system. | Choosing a filter drier not rated for the specific refrigerant. |

| Moisture Removal Capacity | Select based on the system's size and environmental conditions. | Underestimating moisture levels leading to frequent failures. |

| Filtration Efficiency | Look for higher micron ratings for better filtration. | Selecting filters with insufficient micron ratings. |

| Size and Capacity | Match the filter drier size with the HVAC unit capacity. | Using an undersized or oversized filter drier. |

| Temperature Range | Select based on the temperature conditions of the environment. | Ignoring the operational temperature range. |

Filter driers play a crucial role in maintaining the efficiency and longevity of HVAC systems, ensuring that moisture and contaminants do not compromise performance.

To ensure optimal operation, regular maintenance is essential. One key practice is to frequently check the pressure drop across the filter drier. An increase in pressure drop can indicate that the filter is becoming clogged, which can lead to reduced cooling efficiency.

Replacing clogged or saturated driers not only protects the system but also enhances overall HVAC performance.

Filter driers play a crucial role in maintaining the efficiency and longevity of HVAC systems, ensuring that moisture and contaminants do not compromise performance.

To ensure optimal operation, regular maintenance is essential. One key practice is to frequently check the pressure drop across the filter drier. An increase in pressure drop can indicate that the filter is becoming clogged, which can lead to reduced cooling efficiency.

Replacing clogged or saturated driers not only protects the system but also enhances overall HVAC performance.

Another important maintenance tip involves monitoring

system refrigerant levels. Low refrigerant levels can put additional stress on the filter drier, resulting in potential failures. It’s advisable to inspect for leaks and recharge the system as needed to maintain appropriate levels.

Furthermore, keeping the exterior of the filter drier clean from dirt and debris

helps facilitate proper airflow and prevents overheating.

By incorporating these simple maintenance practices, HVAC technicians can extend the lifespan of filter driers and contribute to the overall efficiency of the system.